Technology Roundtable

Autonomous Robots – Automation, Robots/Cobots

Simulation – Digital Twins

REGISTRATION IS CLOSED

Date: May 23, 2024

Time: 5:30 – 8:00 PM

Location: Chris Sprowls Workforce Innovation Hub, 600 E. Klosterman Rd. Tarpon Springs, FL 34689

Technology has always been at the forefront of advances in manufacturing. There are many new technologies currently playing a role in driving manufacturing forward. We will look at these technologies in our Roundtable series.

Speakers:

Sidney Martin

Dr. Martin holds BS and MS degrees in electrical engineering and a Doctorate in Education, focusing on STEM leadership. With a background in manufacturing high-reliability electronic components for space and military applications, he's a licensed professional engineer, project management professional, Lean Six Sigma Master Black Belt, and Scrum Master.

His research focuses on recruiting and retaining underrepresented students in engineering. Dr. Martin's expertise extends to waterproofing electronics, showcased on the Today Show in 2008. He teaches electrical and electronic courses and is an active member of IEEE and ATMAE.

Currently, he's researching and teaching advanced power electronics for autonomous vehicles. Dr. Martin enjoys outdoor activities and lives with his family on the Florida West Coast.

Dr. Martin's presentation explores the evolving landscape of collaborative robots (cobots) in manufacturing. Highlighting their transformative potential, he discusses how cobots enhance productivity and safety alongside human workers. Attendees gain insights into cobot integration, workforce upskilling opportunities, and future advancements reshaping Industry 4.0 factories.

Three Key Takeaway:

1.Cobots Enhance Human Work: Cobots are not meant to replace human workers but to enhance their capabilities, taking over repetitive, strenuous, or, but not necessarily, precision tasks to free up human workers for more complex and creative tasks.

2. Flexibility and Safety: Cobots represent a significant advancement in manufacturing due to their flexibility, ease of reprogramming, and built-in safety features that allow them to work alongside humans without the need for extensive protective barriers.

3. Future Growth and Evolution: The use of cobots in manufacturing is expected to grow and evolve, with advancements in AI and robotics technology leading to broader applications, improved efficiency, and the potential to transform traditional manufacturing practices and job roles.

Dr. Andres Cardenas-Valencia

Dr. Andres M. Cardenas-Valencia is a professor of engineering. He holds a Ph.D. and an M.S. in chemical engineering from the University of South Florida, along with a B.S. from the University of Guadalajara. Over the past 20 years, Dr. Cardenas has performed research and development, at the Center for Ocean Technology at the University of South Florida and at SRI International. Areas of expertise include microelectromechanical systems, Spectrometers (Optical and Mass), novel power supplies, and sustainable water-energy nexus. His work has lead to 20 peer-review publications, 100+ conference proceedings and 18 US patents.

Currently serving as a Principal Engineer at Connectsix LLC and a faculty member at St. Petersburg College, Dr. Cardenas-Valencia remains engaged in both industry and academia. He continues to collaborate on IoT sensing devices while mentoring students and fostering STEM education.

In his upcoming presentation on automation, Dr. Cardenas-Valencia will provide valuable insights into its historical context and evolving landscape, with a focus on its impact on manufacturing globally and in our region. Through his expertise, he will lead an academic discussion on the intersection of AI, R&D, and education in preparing for the future of automation.

Three Key Takeaways:

1. The concept of automation evolves over time: Humankind has relied on the use of machines and platforms to ease human productivity since the industrial revolution (1800’s). Nowadays, automation is much more encompassing with concepts like internet of things. AI has sparked a new generation of trends. Industry 4.0 is here but mostly implemented by large corporations.

2. Automation is good for manufacturing and people in the US. Productivity, reliability, and even safety can be improved by automation in manufacturing. While this is apparent in production lines, social trends will be benefited as jobs will be elevated. A person will not work on the manufacturing line doing repetitive, physical activities that make them sweat. Manufacturing and automation engineers will work on the robots (programming and maintenance) who now perform the repetitive, boring jobs.

3. Future growth and evolution. The presentation will delve into new trends and what the future holds for automation. Industry 5.0 is already being talked about and present in the manufacturing sphere in large companies. Florida regions are getting ready for it. Is the world and our Nation ready for it?

Tom Bruger

Tom is a founder of Digital Twin Marine and started this visionary company in June of 2020 during the height of the pandemic. He did his undergraduate degree at Florida Tech in ocean engineering. He is a consummate engineer and innovator. After college, Tom worked for the American Bureau of Shipping (ABS) as a Marine Surveyor stationed in Louisiana and eventually in Fort Lauderdale, Florida.

Over the eight years Tom spent with ABS, he surveyed over 1,000 vessels in different parts of the world. Upon moving to Fort Lauderdale, he continued his education and graduated from the University of Florida’s MBA program in late July 2021. Tom has a personal goal of bringing new technology to advance the maritime industry.

Three points to takeaway:

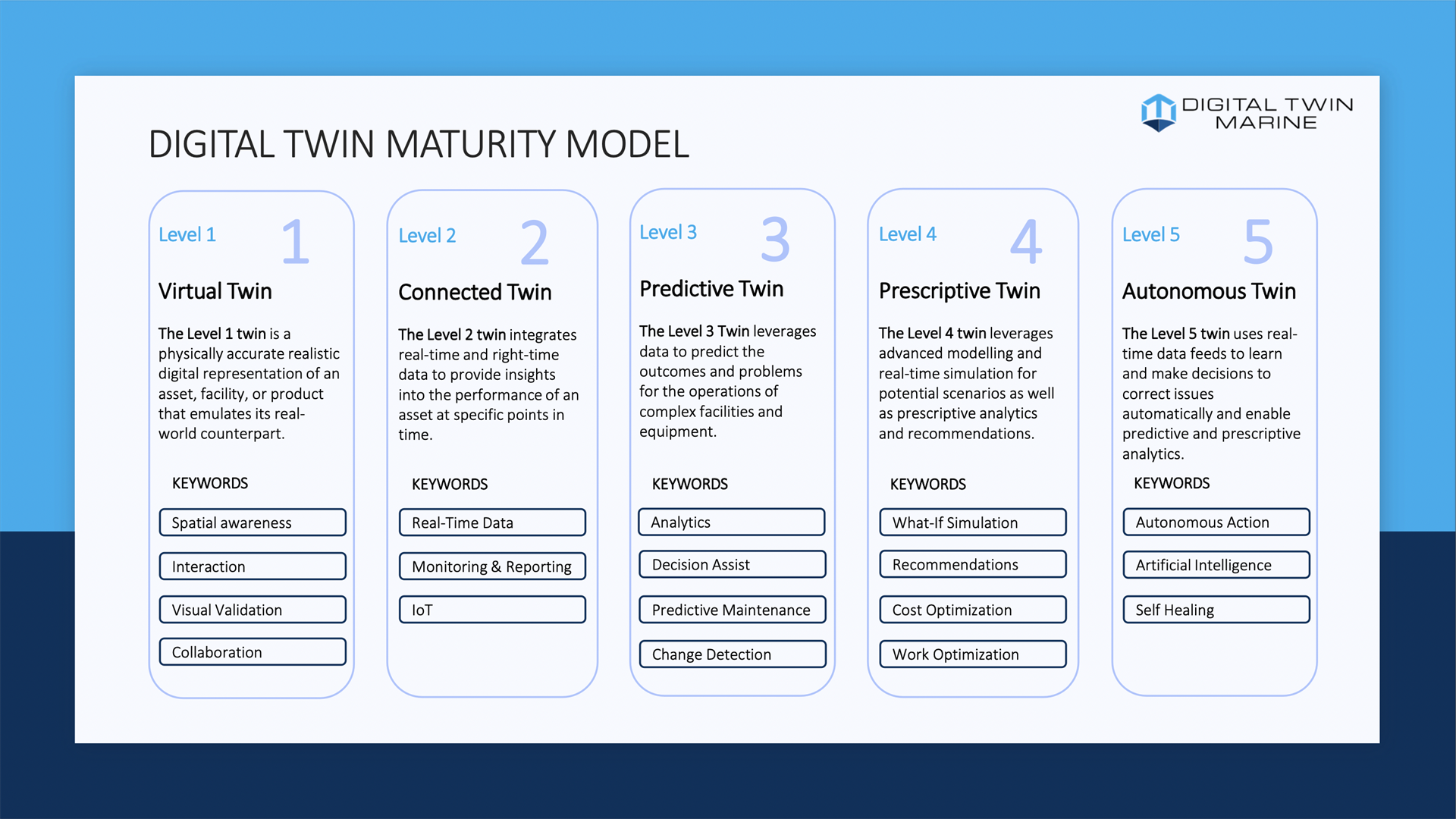

There are five stages of "Digital Twinning"

Digital Twinning is not just what manufacturers may have heard about in Industry 4.0

A digital twin is a virtual representation of an object or system designed to reflect a physical object accurately

Hans Dorries

Founder and Managing Director

Simatron Solutions

In the presentation, I will briefly introduce the concept of the digital twin and its origins. I will focus on the three core components of a digital twin:

- 1. The Model, structured information representing the physical twin through systems such as BIM, GIS, and CAD.

- 2. Simulation and Predictive Analytics, capturing the twin's behavior through tools such as simulation and AI.

- 3. Synchronization, the real-time feedback loop between Operational Technology (OT) and Information Technology (IT).

Three main takeaways:

- 1. Comprehensive Understanding: Attendees will gain a clear understanding of digital twins, including their origins and the critical role they play in modern manufacturing and beyond.

- 2. The Importance of Integration: The presentation will highlight that a digital twin is a holistic concept requiring seamless modeling, simulation, and synchronization integration. This emphasizes the need for multidisciplinary collaboration in its implementation.

- 3. Practical Applications and Benefits: Through examples using FlexSim, the audience will see firsthand how digital twins can be applied to solve real-world problems, improve efficiency, and predict future outcomes, driving home the tangible benefits of this technology in their professional lives.

Butler passed appetizers.

- BAMA Members $25.00 per person

- Non Members: $50.00 per person

Event Sponsor:

.png)

We allow manufacturers and other businesses to take on additional work and grow by providing them the capital they need to execute the PO’s or contracts they have before they ever invoice their customers.

Scott Peper co-founded Mobilization Funding in 2013. Scott’s vision and strategy transitioned a series of investments into the successful business Mobilization Funding is today. Prior to Mobilization Funding, Scott spent 16 years in the medical device industry with Angio Dynamics and Stryker Orthopedics. Before entering the medical device industry, he was the founder and principal of the Wellness Zone, a health and fitness company focused on individual wellness programs for executives. Scott received his Bachelor’s in Business with a concentration in Marketing and Hospitality Management from Keuka College in New York.

Who Should Attend:

Manufacturing Business Owners seeking to gain better control and insight into all facets of their operation, and individuals interested in manufacturing and emerging technologies, eager to harness real-time data to enhance productivity, optimize processes, and foster growth.